What are the different types of screens used in water treatment?

Screening equipment at the headworks is a must-have for any wastewater treatment facility, regardless of size. Large solids such as wood, fabric, paper, and plastics are removed or reduced from the waste stream using screens or pretreatment machines. This not only improves the efficiency of the downstream treatment process, but it also protects the equipment, such as pumps.

To achieve these goals, a variety of equipment can be used, and there is no one-size-fits-all solution that can be applied to every headworks situation. Low flows, limited space, and financial constraints are some of the drawbacks of small systems.

Screens, like other plant equipment, exist in a variety of sizes, capacities, automation, and costs. Screens are classed as coarse, fine, or micro in general, depending on the size of the screening holes.

What are manual bar screens?

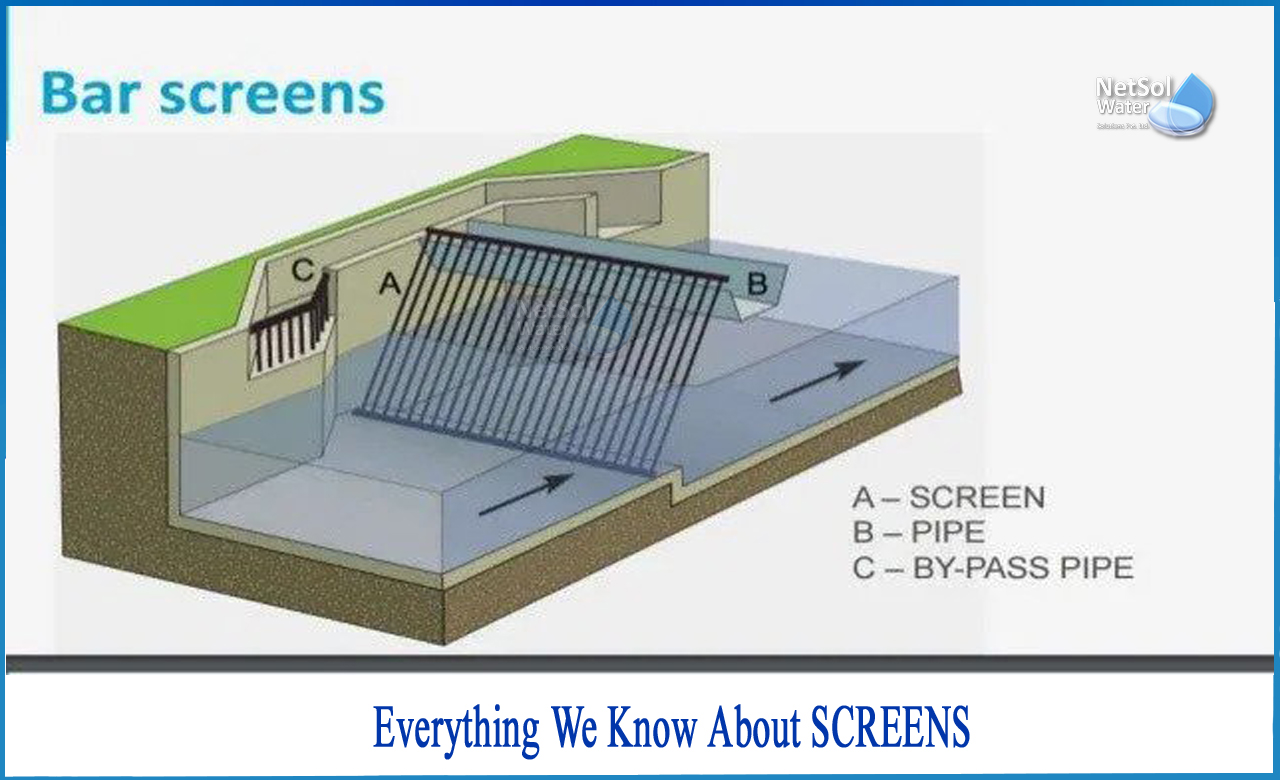

A manual bar screen may be a wonderful alternative for small systems due to their constraints. To collect entering debris, these screens contain vertical bars spaced 1 to 2 inches apart. They give a good level of protection for the plant, despite their simplicity. There are, however, restrictions, as with any basic equipment.

The most obvious disadvantage is that this is a manual activity that necessitates committed labor and might be prohibitively expensive for small systems. This is especially true during high-flow events like storms, which may necessitate more frequent raking and pose a greater risk to the operator's safety.

What are automatic bar screens?

There are various automated methods available to reduce the labor needed with manual bar screens. These can be categorized into several types of groups. There are several types of screens, including chain driven screens, catenary screens, reciprocating rakes, continuous belt screens, and many others.

Vertical bars are typically used to gather solids and remove them with an automated rake system in these choices. Because these are automated, the cost as well as other operational expenditures must be taken into account. Furthermore, because these systems are larger than the manual screen, installing one to a facility may necessitate civil engineering modifications to the influent channel.

You may have cut labor costs, but you could raise capital and infrastructure costs.Although course screens can remove considerable amounts of debris at the headworks, disposal is an additional cost that necessitates operation and maintenance. Furthermore, the stinky wet screens gathered can attract rodents and cause odor complaints from the neighbors.

Table below summarizes the various types of displays, along with their benefits and drawbacks-

Type of screen |

Advantages |

Disadvantages |

|

Chain or cable driven screens |

For many years, the design has been in the market. -Constructing a simple channel -A high rate of screenings loading -Fat, oil, and grease insensitive (FOG) -Minimum headroom is required. |

Components submerged in water are prone to wear and tear. |

|

Reciprocating rake screens |

-There are no submerged vital components. -Frequently used |

-Low loading rate for screening -High clearance above the water, especially in deep channels |

|

Continuous self-cleaning screens |

-Headroom is necessary in the range of medium to low. -Allows for a pivot design so that the unit can be serviced above the channel. |

-There are several moving parts. -Components that are prone to wear and damage |

|

Arc screens |

-The design is straightforward. -Reduced capital and operating expenses -Underwater, there are no drive parts. Uses the entire width of the channel |

-Plants with a modest to medium -flow rate are restricted. -Deep channels are not recommended. |

|

Catenary screens |

-Operation is simple. -Simple to keep up with |

-Chains are heavy and difficult to manage, and they have a large footprint. |

Performance of the screens

The efficiency of screenings is determined by the collection system's length and slope, as well as the existence of pumping stations. Because of solids disintegration, fewer screens are created when the collection system is lengthy and steep, or when pumping stations are present. Other elements that influence screening numbers include flow, since quantities tend to rise dramatically during storms.

Maintenance and operation of screens

To avoid clogging, manually cleaned screens must be raked on a regular basis. The frequency of cleaning is determined by the characteristics of the wastewater entering the plant.

Screening mechanisms, such as basket-style waste racks, have been installed into some plants and are manually hoisted and cleaned. Because screenings are scraped using a mechanical instrument, mechanically cleaned screens usually require less work to operate than manually cleaned screens rather than by the facility's staff.

The rake teeth of mechanically cleaned screens, on the other hand, must be inspected on a regular basis due to their proneness to breaking and bending. To avoid fouling by grit and rags, drive mechanisms must be inspected on a regular basis. Grit that has been removed from screens must be disposed of on a regular basis.

Conclusion

In conclusion, there is no one-size-fits-all solution for all headworks screening scenarios.

Individual considerations including flow rate, solids loading, cost, and infrastructure changes must all be taken into account. It's critical to pick the right alternative not only to protect downstream equipment, but also to ensure efficient and effective solids removal and adequate wastewater treatment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.