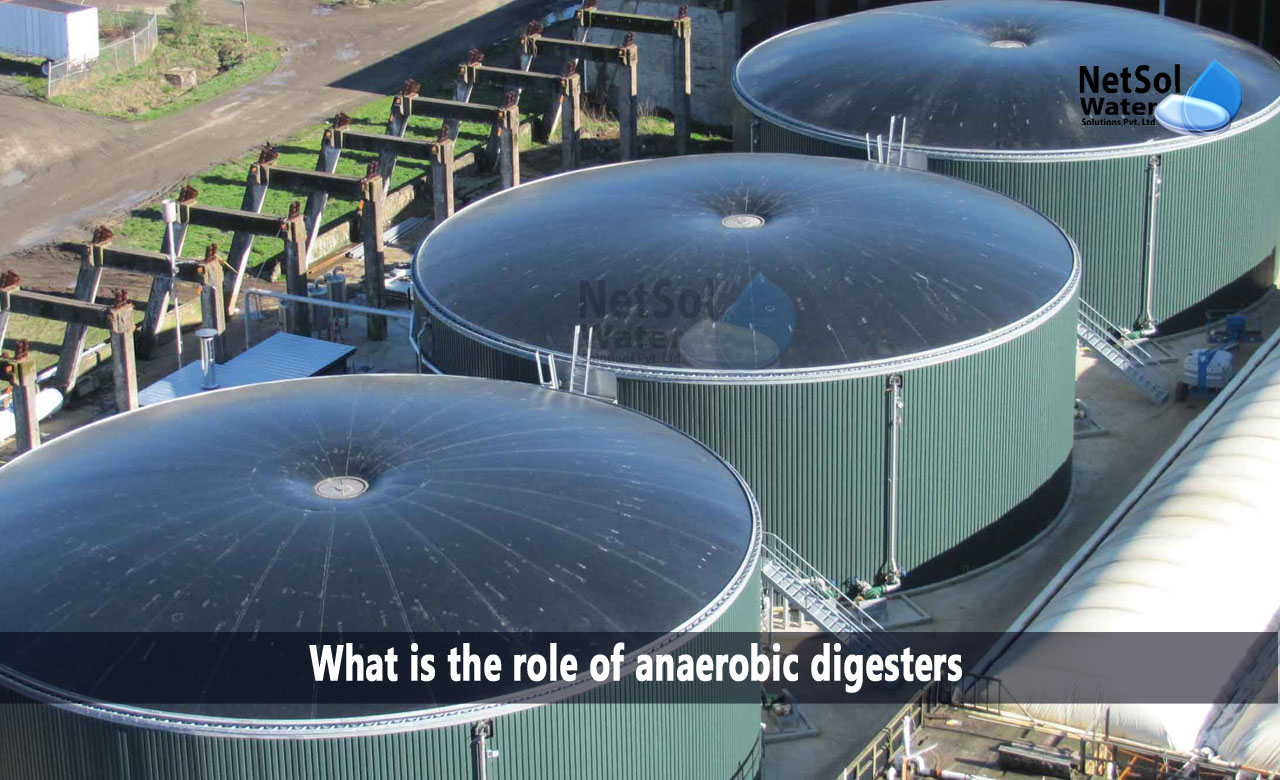

What is the role of anaerobic digesters?

Anaerobic digestion (AD) is a biological process that uses bacteria to biodegrade organic matter (feedstock), in the absence of oxygen. It offers a variety of advantages in the treatment of difficult wastewater streams, as well as the chance to create value in the process.

Let’s understand the role of anaerobic digesters in wastewater treatment!

Biogas, one of the most valuable commodities often recovered from the process, is produced as energy by anaerobic digestion. Up to 70% of the produced biogas is methane, which can be used to run electrical generators and cut the energy costs at the treatment plant. Some facilities achieve energy net zero or even generate excess energy, which can be traded.

Working of anaerobic digesters

The bacteria that digest the feedstock, which can include manure, food scraps, fats, oils, and greases (FOG), industrial organic waste, and sewage sludge, require a warm atmosphere to thrive in order to produce methane. The digester's top is where the biogas, a result of digestion, rises to be collected.

It can be used to power vehicles, fuel engines that provide mechanical power, heat, or electricity, fuel boilers, digesters, and houses and businesses via the natural gas pipeline.

Biogas is commonly processed to remove water, carbon dioxide, and other impurities in order to boost value. Internal combustion engines typically use lower-grade biogas, whereas more sensitive and efficient engines require higher grades.

Anaerobic Digester Outputs

1: Biogas

Methane (CH4), the main component of natural gas, makes up between 50% and 75% of biogas along with carbon dioxide (CO2), hydrogen sulfide (H2S), water vapour, and trace amounts of other gases.

Like natural gas, biogas can be utilized for a variety of purposes, including the production of electricity, the operation of cooling systems, and the provision of heat. In order to produce sustainable natural gas, biogas can also be processed by eliminating the inert or low-value ingredients.

This can be used to power vehicles, sold and pumped into the natural gas distribution system, compressed, or further processed to produce sophisticated bio-chemicals and bio-products, alternative transportation fuel, and energy products.

2: Digestate

Digestate is the waste product of the digestive process. It is made up of both liquid and solid components. Due to the fact that each of these has value that can be realized to varied degrees through post processing, they are frequently separated and handled separately.

With the proper processing, digestate's solid and liquid components can be used in a variety of advantageous ways, including as animal bedding (solids), nutrient-rich fertilizer (liquids and solids), a building block for bio-based products (such as bio-plastics), organically rich compost (solids), or just as a soil amendment (solids).

The latter option may involve the farm applying of the digestate to the fields as fertilizer. Digestate products can be a source of income or cost savings, and they are frequently sought after to boost an AD/biogas project's financial and net environmental benefits.

Conclusion

Anaerobic digestion uses a waste-to-energy system to produce biogas, which is then transformed into electrical and heat energy by a co-generator. Primary sludge is next dehydrated, and the process is completed by processing the effluent, through a nitrification-denitrification system and a final clarifier.

Anaerobic digestion is used by Netsol Water to transform a waste product into energy. The AD process itself has few operational and maintenance requirements and is dependable. It reduces the amount of sludge that needs to be dumped in landfills by up to 90%, and minimizes greenhouse gas emissions. It has also been demonstrated to lessen water-borne microplastics.

For further information, contact us at +91 9650608473 or email at enquiry@netsolwater.com